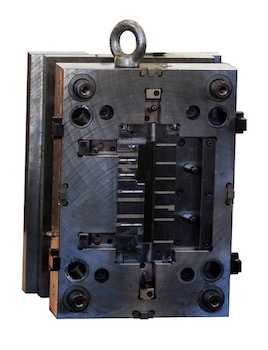

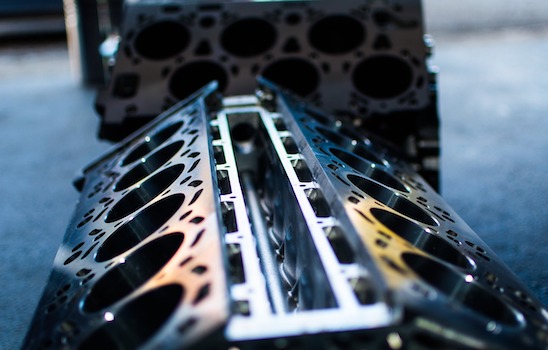

Engineering and Design

At Arg Azin Die Casting, our team of highly skilled and creative engineers takes precision to a new level from the earliest stages of your project throughout the final production of your parts. We offer a wide range of engineering solutions for die-cast production including but not limited to prototype services along with product and tooling design to ensure customer satisfaction while improving both the quality and efficiency in each individual phase of the engineering and production process. We use the latest computer engineering software that can create an initial prototype of your file to determine if improvements are necessary before full production. We also provide reverse engineering and offer guidance in alloy selection and in geometric dimensioning. With the help of our engineering professionals, you’re guaranteed a top of the line product that only we can provide here at Arg Azin Die Casting.